Wilo Pumps have been around for a few years and are a reliable and durable range of pumps available to our business.

When it comes to Wilo Pumps, our team believes in quality, durability and reliability and these are qualities that we seek when sourcing the best products. Taking this into consideration, we all know, Australia has some of the harshest weather conditions. So, in order to make it easier on our customers, we as a team like to seek a good range of pumps on behalf of our customers.

As a business, customer satisfaction is our main focus when it comes to any product in our range. Please be aware, that this is not a shopping site, but it is a site where we have information on Wilo Pumps. If you need help with any project big or small, or are looking to find a product, just contact us. Our great team are very knowledgeable when it comes to the Wilo brand product range.

So, if you would like to check out the Wilo Pumps range, have a browse in the catalogue below. If you prefer to check out our other suppliers and more of our range of pumps just click here.

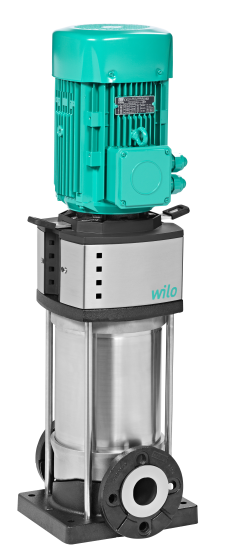

Wilo-Helix V

High efficiency non-self priming vertical multistage pumps.

Your advantages

Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

Corrosion-resistant impellers, guide vanes and stage housings

Flow and NPSH-optimised pump housing

Maintenance-friendly design with particularly robust coupling guard

Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Construction

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections

Application

Water supply and pressure boosting

Industrial circulation systems

Process water

Closed cooling circuits

Fire extinguishing systems

Washing systems

Irrigation

Equipment/function

Corrosion-resistant impellers, guide vanes and stage housings

Scope of delivery

Helix V high-pressure multistage centrifugal pump

Installation and operating instructions

Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

Technical data

Electrical connection:

3~400 V (±10 %), 50 Hz

≤ 4 kW 230 V/ 400 V; Δ/Y

> 4 kW 400 V/ 690 V; Δ/Y

• 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

Fluid temperature range:

Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

Max. operating pressure: 16/25/30 bar

Max. inlet pressure of 10 bar

Protection class: IP 55

Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

Available versions:

Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix V 2, 4, 6, 10, 16:

Standard version

Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

Pump housing made of stainless steel 1.4301 (AISI 304)

Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

Sleeve under the mechanical seal 1.4404 (AISI 316L)

O-ring of EPDM (FKM gasket on request)

Jacket pipe made of stainless steel 1.4301 (AISI 304)

For aggressive media

Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

Pump housing made of stainless steel 1.4404 (AISI 316L)

Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

Sleeve under the mechanical seal 1.4404 (AISI 316L)

O-ring of FKM (EPDM gasket on request)

Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Helix V 22, 36, 52:

Standard version

Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

Shaft made of stainless steel 1.4057 (AISI 431)

Sleeve under the mechanical seal 1.4404 (AISI 316L)

O-ring of EPDM (FKM gasket on request)

Jacket pipe made of stainless steel 1.4301 (AISI 304)

For aggressive media

Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

Baseplate made of stainless steel 1.4301 (AISI 304)

Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

Sleeve under the mechanical seal 1.4404 (AISI 316L)

O-ring of FKM (EPDM gasket on request)

Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

Pumps can be adapted to specific circumstances on request (e.g. motor protection, IE4 motor efficiency class, VdS certified Wilo-Helix pumps, ATEX, extended ambient temperature range).

The Helix series is also available with an integrated frequency converter.